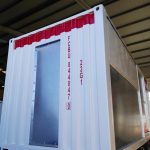

Proinsener Solar inverter stations are designed and integrated specifically for each project. It is an easily installable and compact product perfect for generating solar power on a large scale. All this allows easy and quick field connection to the medium voltage transforming station (MV), which reduces transport and installation costs.

Proinsener offers this solution in standard containers, in metal skids or in prefabricated concrete buildings according to the requirements of the project, always guaranteeing in any solution safe and affordable transportation to any part of the world.

In each inverter station all of the necessary equipment is integrated to connect to the medium voltage network of the photovoltaic plant, always complying with the standards of performance and quality required according to the project and its location. Currently Proinsener has installed inverter stations under very demanding environmental conditions, which allowed us to develop solutions for the best manufacturers of power electronics in the market.

Our custom-made turnkey designs optimize space and performance. The integration of this type of station is consist of medium voltage panels, low voltage panels, UPS, air conditioning units, auxiliary systems and all other technical requirements of our customers.

Features

- Resistant to demanding climatic conditions. deserts, areas with risk of typhoons, high humidity, high seismic activity, etc.

- Resistance to fire propagation. rated as RF120, capable of containing an internal fire for at least 120 minutes.

- Indoor or outdoor transformer. According to needs.

- MV Panel. Possibility of integration inside the inverter station or in cabins, specially designed and manufactured for the integration of external cells.

- LV Panel. Design and integration according to characteristics of inverters and transformers.

- Connection MV and LV bridges.

- Inverter integration. Integration of one or more inverters according to the manufacturer. Including level 2 boxes and continuous-to-inverter bridges if required.

- Ventilation. Internal temperature control by means of an automatic system of forced ventilation or natural ventilation.

- Control and measurement.

References

PV Plant de Camargo

Location: Camargo, Mexico

Type: 20 ‘ DV container

Power: 14 Stations 2.2 MW

PV Plant El Romero

Location: Chile

Type: 40 ‘ HC container

Power: 60 Stations 3.6 MW

Intipampa

Location: Intipampa, Peru

Type: 40 ‘ container

Power: 9 Stations

Namibia PV Plant

Hotel Area: Namibia

Type: 40 ‘ HC container

Power: 9 Stations 4.6 MW

Benban

Location: Benban, Egypt

Type: 20 ‘ container

Power: 66 Stations 240 MW

La Orejaa

Location: Hermosillo. Mexico

Type: 40 ‘ HC containers

Power: 28 Stations 143 MW

PV Atacama Plant 1

Location: Atacama. Chile

Type: 20 ‘ containers

Power: 50 Stations 115 MW

Jordan Investor Station

Location: Jordan

Type: 40 ‘ container

Power: 2.8 MW

Quilapilun

Location: Quilapilun. Chile

Type: 40 ‘ container

Power: 4 stations 20 MW

Egmere and Parley

Location: Egmere. Uk

Type: 40 ‘ container

Power: 11 Stations 1.6 MW

Combarbala

Location: Coquimbo. Chile.

Type: 20 ‘ HC container

Power: 1.25 MW

Sun Metals PV 120MVA

Location: Townsville. Australia

Type: 40 ‘ and 20 ‘ containers

Power: 24 Stations of 4.9 MW and 2 stations of 3.28 MW

PV Sun Orchard

Location: California. Usa

Type: Metal Skid

Power: 19 Stations 26.6 MW

Villa Ahumada

Location: Villa Ahumada. Mexico

Type: Metal Skid

Power: 32 Stations 164 MW

Icacos 44.8 MW

Location: Penonome. Panama

Type: Metal Skid

Power: 19 Stations 2.8 MW

Buria-Mica

Location: Buria Mica. Romania

Type: Precast concrete Building

Power: 1.5 MW